Forming shoulder for stickpacks

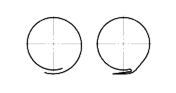

Application Cross-section: rectangular or round with centered seal Types of seal: lap seal, distant seal and turned fin seal Bags with a flat bag width…

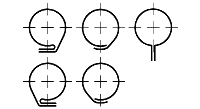

Stickpack, ApplicationCross-section: rectangular or round with centered sealTypes of seal: lap seal, distant seal and turned fin sealBags with a flat bag width of less than 60 mm are called stickpacks. The flat film is formed into a tube with the seal concealed completely within the forming shoulder.We also develop stickpack forming shoulders for paper for your special needs.We are not limited to a minimum flat bag width. The smallest forming shoulder we have ever manufactured was for a flat bag width of 6 mm. Our entire stickpack forming shoulders are milled and thus ideal for multilane purposes. Each forming shoulder of a series is identical to any other.Forming shoulders with a flat bag width exceeding 60 mm are usually called universal forming shoulders. They are made of sheet metal and their application in multilane machines is limited.Benefitsreliable forming processreduced forming height and improved stability compared to a forming process that does not utilize forming shouldersimproved stability of film run compared to a process that utilizes heads of forming shouldersno special qualification required for installation and operation of the forming shoulderideal for the application in multilane stickpack machinesLimitationscostly manufacturing and testing processesfrequent adoption to new film material and process conditions necessary Find information on how to open stickpack forming shoulders easily using the “easy-to-open” mechanism

Horizontal forming shoulder

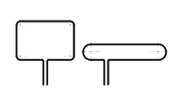

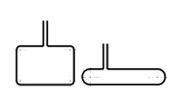

Application We also develop horizontal forming shoulders for paper for your special needs. form of the seal: centered or shifted lap or distant fin seal…

, ApplicationWe also develop horizontal forming shoulders for paper for your special needs.form of the seal: centered or shifted lap or distant fin sealinfeed of film: from topHorizontal forming shoulders are applied to the packaging of piece goods. They are also known as folding boxes or flowpack forming shoulders.Our forming shoulders are suited especially for use in high-speed flowpack packaging machines.Benefits wrinkle-free formingminimum installation effortLimitsDue to the infeed of the film from top the piece goods have to be pushed within the forming shoulder. Thus the design of the forming shoulder depends on the geometry of the conveyor and the pitch point of the driving pin.Get more information about why forming shoulders are applied to horizontal bag making machines

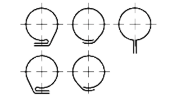

Forming shoulder for stickpacks “easy-to-open”

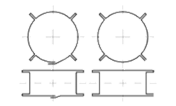

By employing movable parts, the usually closed forming shoulder is rendered more accessible.Under normal circumstances forming shoulders are closed. Moveable front parts improve accessibility. The…

, By employing movable parts, the usually closed forming shoulder is rendered more accessible.Under normal circumstances forming shoulders are closed. Moveable front parts improve accessibility. The handling of film is much faster and safer, especially when used in multilane forming sets.StructureForming shoulders of the “easy-to-open” design consist ofa body which is mounted on the machinemoveable front parts, which can be opened and closed by a sliding mechanismAll parts are designed to move safely and without impacting any other parts when operated side by side.BenefitsReduced setup time as well as time savings when changing and cleaning the parts on account of the simplified handling of the filling tubesuitable for multilane forming setsRead more about the “easy-to-open” mechanismopened forming shoulders of a stickpack forming setclosed forming shoulders of a stickpack forming set

Forming head – uForm

Application filling pipe: round or rectangular types of seal: centered lap seal or centered distant or turned down fin seal A forming head is not…

, Applicationfilling pipe: round or rectangulartypes of seal: centered lap seal or centered distant or turned down fin sealA forming head is not a finished forming shoulder but the first step in the forming process that forms the film into a flat tube. The second step then moulds and calibrates the tube into its final form. The required parts have to be manufactured and integrated into the machine by the customer himself.The forming parts have to be adjusted precisely to the forming head . We supply a sketch to show where the forming parts should be situated. Finally it depends on the customer where the forming parts are positioned.Especially low-priced we offer a series of standardized forming heads suitable for bags with a flat bag width from 13 mm to 42 mm. Get an overview and have a look at the data sheet of the uForm series (pdf file)Benefitscompetitive low investment costsreduced forming length andimproved film run compared to a forming process without a forming shoulderapplicable to multilane machinesLimitsqualified personnel for installation and operation requiredinferior film run compared to a forming process with a forming shoulderSample applicationMultilane stickpack machine with ten forming heads

Forming shoulder for double-front sticks

Application cross-section: round or rectangular with seal on the edge types of seal: lap seal, distant or turned down fin seal This is the only…

, Applicationcross-section: round or rectangular with seal on the edgetypes of seal: lap seal, distant or turned down fin sealThis is the only type of forming shoulder allowing you to manufacture – with your standard machine – the double-front stick: a bag with the seal placed on the edge of the bag. All you have to do is to laterally shift the longitudinal sealing jaw, install the forming shoulder and initiate the manufacturing process.BenefitsExtended product range of standard bag forming, filling and sealing machinesReliable tube forming in one single stepSuitable for multilane machinesLimitationsThe dimensions of forming shoulders for double front sticks are larger than those of stickpack forming shoulders of the same format but with centered seals.An application for a patent has been filed.Find out more about the double-front stick

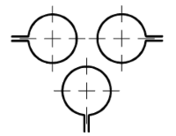

Three-side sealed bags

Application filling tube: round or rectangular form of the seal: protruding fin seam on the side or in the middle These Forming shoulders are used…

, Applicationfilling tube: round or rectangularform of the seal: protruding fin seam on the side or in the middleThese Forming shoulders are used in the production of a classic bag shape, the three-side sealed bag. It is applied to packages of small portions e.g. of sugar, mustard or tomato ketchup but also for bigger bags.We offer two different versions of this forming shoulders:with distant fin seal in the centre of the bag (symmetric forming shoulder)with distant fin seal on the edge of the bag (asymmetric forming shoulder)BenefitsThe symmetric forming shoulder saves installation space and offers a small falling height for your product. The asymmetric forming shoulder variant is ideally suited for use in standard tubular bag machines. The arrangement of all assemblies remains the same. The film running direction is retained. Only the welding element for the longitudinal seam has to be able to be moved laterally.easy to integrateincrease the diversity of the products your standard machine is able to produceapplicable to multilane machines.LimitsCompared to a standard tubular bag machine, the symmetrical forming shoulder variant requires a film infeed rotated by 90°.The asymmetrical forming shoulder variant requires a greater forming shoulder height compared to the symmetrical forming shoulder variant.Find out how to make three-side sealed bags from a double tube.

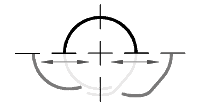

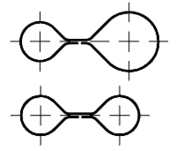

Forming shoulder for double-chamber bags (TwinForm)

Application filling cross-section: round form of seal: centered end-to-end, two distant fin seals TwinForm forms a double tube. This double tube is used to pack…

, Applicationfilling cross-section: roundform of seal: centered end-to-end, two distant fin sealsTwinForm forms a double tube. This double tube is used to pack two individual products into a double-chamber bag. It may also be used to pack one product into two three-side-sealed bags.Benefitsuitable for fragile products due to a small height of TwinFormstable film formingwide openings of the film makes filling the chambers easyreduced amount of forming parts makes TwinForm especially suitable for easy cleaning applicationsTwinForm is patented.Get information about forming a double tube

Universal forming shoulder

Application cross-section of filling tube: round form of the seal: centered lap and turned-down fin seal, right side over left side Universal forming shoulders are…

, Applicationcross-section of filling tube: roundform of the seal: centered lap and turned-down fin seal, right side over left sideUniversal forming shoulders are efficiently manufactured forming shoulders for bags with a flat bag width between 50 mm and 250 mm. Two different series are offered in our brochure “universal forming shoulder”. Besides price information the brochure gives the dimensions of each forming shoulder. Due to the pre-defined dimensions of the forming shoulder the design process of the machine can be faster.Series ffcompactForming shoulder series ffcompact is developed for machines which offer only a little installation space. The infeed angle is rather small and causes more stress on the film material compared to a forming shoulder with a higher infeed angle. We suggest applying resilient film materials like mono-plastic films on these forming shoulders.Series ffcomfortThis forming shoulder series offers an infeed angle of 45°. It is therefore also suitable for more sensitive laminated films. Due to the constant infeed angle we offer the option “infeed rolls” for this series. Infeed rolls align the film run to the surface of the forming shoulder in the most suitable way. By choosing this option two infeed rolls are attached to the infeed of the forming shoulder.Benefitsreasonably pricedBoth lap seal and fin seal may be produced with one forming shouldersimply obtain spare parts due to standardized dimensionsseries ffcompact: small height of the forming shoulderLimitsapplicable film materials: only mono-plastic and laminated-plastic film without layers of paper.Obtain the brochure of the universal forming shoulders

Forming shoulder for QuadSeal gusset bags

Application filling tube: round or rectangular form of seal: centered or shifted lap or turned-down fin seal Bags with sealed gussets are more rugged compared…

, Applicationfilling tube: round or rectangularform of seal: centered or shifted lap or turned-down fin sealBags with sealed gussets are more rugged compared to bags without sealed gussets. They provide even areas for the information and the advertising on every side of the bag.A QuadSeal forming shoulder forms the film tube and the gussets continuously in one forming process, keeping the falling height of the product is small.Benefitsrequires small installation spaceone-step forming of the complete gusseted film tubeProducing sealed gussetsWhile pulling the film tube the guiding parts of the QuadSeal forming shoulder and the forming tube form the gussets continuously. The gussets are sealed directly below the forming shoulder by the sealing equipment.

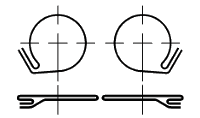

Inverse horizontal forming shoulder

Application form of the seal: centered or shifted lap or distant fin seal infeed of film: from bottom Inverse horizontal forming shoulders are applied to…

, Applicationform of the seal: centered or shifted lap or distant fin sealinfeed of film: from bottomInverse horizontal forming shoulders are applied to the packaging of piece goods. The design of the feeding system, which transports the piece goods into the forming shoulder, is less complex due to the transfer point between conveyor and forming shoulder being a simple straight edge.Benefits wrinkle-free formingminimum installation effortthe sealing- and pulling-off rolls are good accessiblesimple design of the infeed system

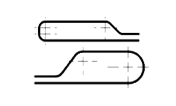

Longitudinal corrugator

Application The longitudinal corrugator was invented as a device for the corrugation of paper. It is the basis for the production of longitudinal corrugated cardboard…

, ApplicationThe longitudinal corrugator was invented as a device for the corrugation of paper. It is the basis for the production of longitudinal corrugated cardboard or cross-corrugated cardboard. It is conceivable that not only paper but also plastic, woven and non-woven fabric or tin foils can be applied as raw material.The longitudinal corrugator is one of our products. We design and manufacture the longitudinal corrugator exactly for your application.CharacteristicsThe film material is formed by the longitudinal corrugator. The forming process is similar to that of an extruder. Theoretically the corrugated profiles can be produced with an endless length. The geometry of the profiles to be formed can be designed nearly without restrictions.The longitudinal corrugator is effectively applicable to the production of cross-corrugated cardboard or honey-comb cardboard. Even applications beyond the processing of paper were realized.BenefitsOptimum film run and re-production is possible due to an exact calculated Design.Longitudinal corrugator manufactured in best quality due to in-house manufacturing.LimitsOptimal for the processing of continuous product streams.Up to now each longitudinal corrugator has a fixed format.Read more about the longitudinal corrugating technology

Three-side sealed bags, produced horizontally

Application form of seal: distant fin seal on the edge of the bag infeed of film: from bottom The horizontal machine concept is used if…

, Applicationform of seal: distant fin seal on the edge of the baginfeed of film: from bottomThe horizontal machine concept is used if the goods are fragile or heavy or the order of a stack has to be kept.Three-side sealed bags are suitable especially for aseptic packaging. There are no leaps of the layers in the seals. Therefore the bags are impermeable. The inverse horizontal forming shoulder for three-side sealed bags forms the longitudinal fin seal to the edge of the bag. The cross-section of the film tube is rectangular with rounded edges.Benefitswrinkle-free formingthe sealing- and pulling-off rolls are easily accessiblesimple design of the infeed systemLimitsincreased length of the forming shoulder due to its asymmetric design

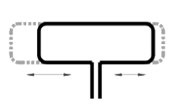

Adjustable horizontal forming shoulder

Application parent forming shoulder: horizontal forming shoulder film tube: rectangular with rounded edges form of the seal: centered or shifted distant fin seal. infeed of…

, Applicationparent forming shoulder: horizontal forming shoulderfilm tube: rectangular with rounded edgesform of the seal: centered or shifted distant fin seal.infeed of film: from topBenefitsadjust the width of the forming shoulder via an easily accessible mechanismwrinkle-free forming in every positioninstantly applicable to an existing bag making machineLimitsThe setting range of the width is limited to the installation space provided.Read more about the mechanism to adjust the width of the format continuously